News - Press Release

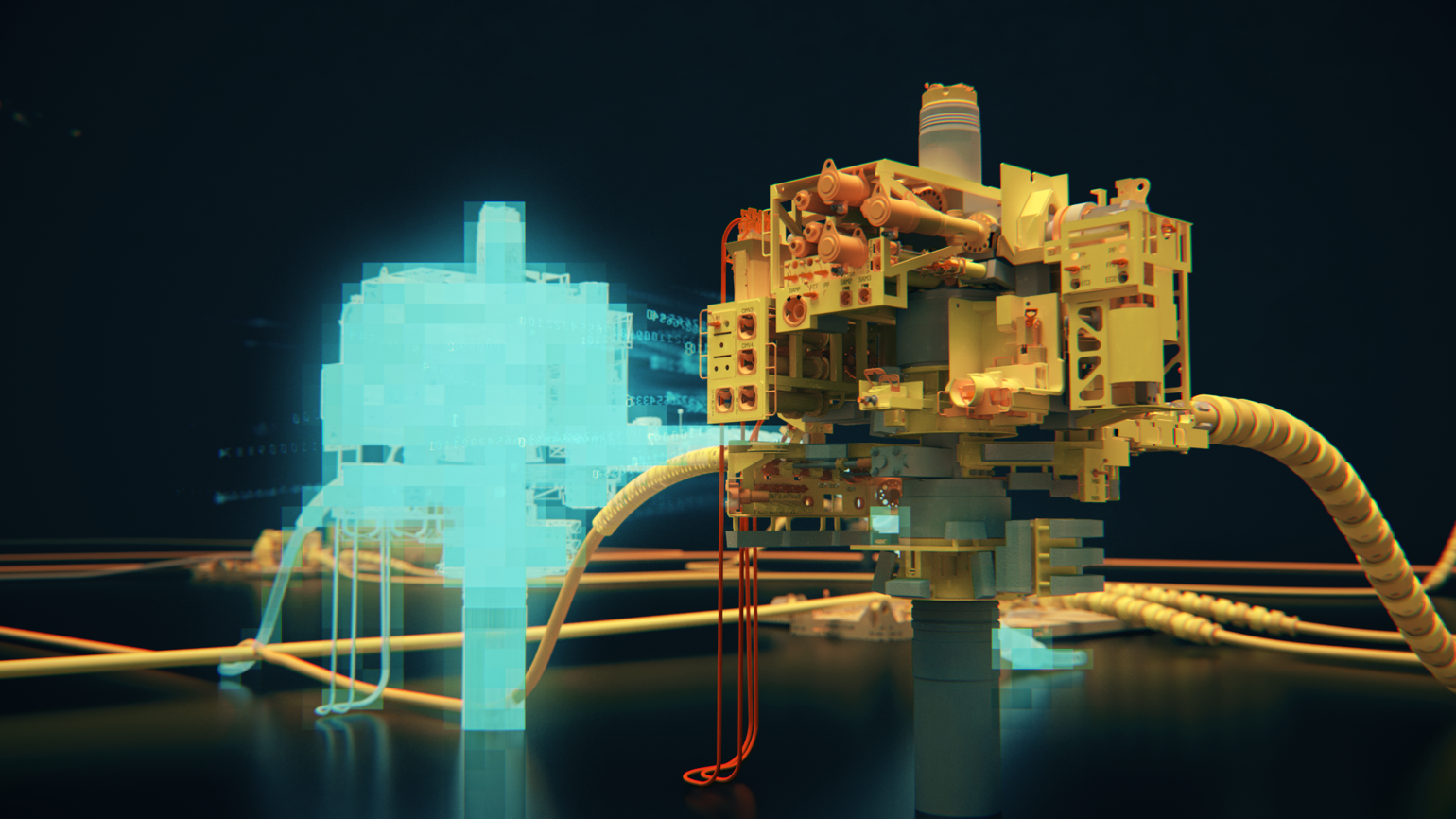

As a virtual representation of a system or asset to provide decision support over its lifecycle, subsea digital twins ensure that system information is widely available in real-time, providing decision support over its lifecycle and enabling more effective collaboration.

TechnipFMC’s subsea digital twin offering utilizes our Subsea StudioTM portfolio of digital solutions and our cloud-based architecture to connect all relevant data throughout the lifecycle of a field. Static and dynamic data is incorporated into our data platform from multiple core systems during field development, tender, execution, and operation. That information is then contextualized in our data models to provide high-quality insight.

Data insights

User-centric applications are designed to improve performance and enhance decision-making from data insights. Our digital ecosystem enables secure access for internal and external users to the digital twin applications. Data can also be exchanged with clients, suppliers, and third-party platforms for efficient execution and connected solutions.

Within our digital twin framework, Subsea StudioTM is our collaboration portal that connects data about TechnipFMC’s installed base, assets in storage, tools, and spares related to our internal process applications. Our operational data are then used to optimize the performance of our products and services, and enable collaboration within our engineering teams ,to leverage continuous improvements and innovation to support and deliver our customer services excellence every day.

The information flow is automated and on-demand, removing cumbersome transactions between systems and the risk of human error and oversight. Insights on product and services will be instant, allowing for optimized designs with improved reliability for our clients.

Partnerships with DNV

To provide a robust digital twin, we must be able to trust the data and insights provided. TechnipFMC identified the need for an industry standard to ensure safety, quality and robustness, and we developed in close collaboration with DNV the industry’s first recommended practice for quality assurance of digital twins. This standard, DNVGL-RP-A204, was released in October 2020. It provides guidance on:

- assessing whether a digital twin will deliver to stakeholders’ expectations from the inception of a project

- establishing confidence in the data and computational models that a digital twin runs on

- evaluating an organization’s readiness to work with and evolve alongside a digital twin.

Moving business forward

Subsea digital twins are enabling new business models and ways of working. Contracted services are efficiently based on condition, overview of spare parts, tools, vessels, personnel, and other relevant information. The information flow will be automated and on-demand, removing cumbersome transactions between systems and reducing the risk of error. Insights on product and services will be instant, allowing for optimized designs with improved reliability. Subsea digital twins will allow the industry to shift towards a proactive mindset, where recommendations for integrated services are available instantaneously.

More news

-

News | May 06, 2025

TechnipFMC Advances Hybrid Flexible Pipe Technology Innovation in Collaboration with Petrobras

-

News | March 18, 2024

Inside HISEP® – How TechnipFMC is taking dense gas separation and storage fully subsea

-

News | October 19, 2023

TechnipFMC wins NOIA ESG Excellence award