Wellheads and trees

Minimize your flat time and reach total depth faster with TechnipFMC's onshore and offshore wellheads.

We are a technology leader focused on innovation, quality and customer support. Our field-proven wellheads and trees are designed to meet customer needs and minimize non-productive time.

TechnipFMC has been providing wellheads solutions globally for more than 80 years. We have invested heavily in engineering, development and manufacturing capabilities to deliver our customers consistent and reliable wellheads. We offer our customers a comprehensive portfolio of Surface wellheads covering all well applications from conventional and time-saving systems to high performance unihead systems.

Our global operations feature manufacturing hubs, sales offices and field bases in all major oil and gas producing regions of the world. We are constantly looking for ways to improve our advanced wellhead technology to shorten the cycle time to production, cut operating costs and reduce non-productive time.

Shale

Performance and reliability

To ensure consistent performance and reliability, we train our field service technicians at our learning pad centers around the world. This stringent-comprehensive training consists of in-class and on-the-pad education. Our product development process is rigorous, ensuring our product validation is more than API 6A testing requirements.

Our skilled field technicians make certain our wellheads are delivered and perform as expected. As experts in oil and gas wellheads, you can expect us to remain your partner throughout the lifecycle of the well.

Engineering and design

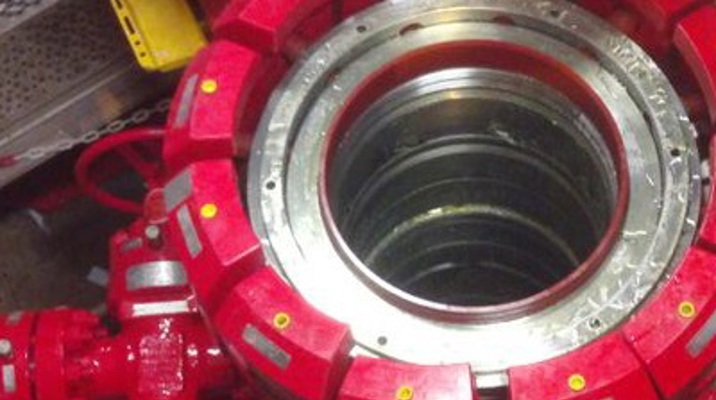

Our core wellhead technologies, such as seals and gate valves, provide exceptional reliability and integrity for all our wellheads in both low-temperature and high-temperature operations. We offer a full range of exploration, drilling, completion and production wellheads for onshore, offshore and shallow water applications. We are constantly innovating as we tackle new industry challenges and leverage the latest manufacturing technology to lower costs and improve production.

We design our wellheads to be versatile to allow for multiple casing programs with the same wellhead and to accommodate solid or fluted mandrel hangers and specialty equipment such as ESP's, downhole sensors and control lines.

Project execution

Our wellhead technology greatly increases safety performance and execution by reducing time on location. Our wellheads use mandrel hangers in combination with our SafeLatch™ technology to remove the need to work under a suspended blowout preventer. Our speed wellheads minimize drilling time by eliminating the wait for cement setting.

Our track record of project execution shows our projects are delivered on time, reducing risk for our customers. Our internal competency on critical processes includes cladding, big bore machining and tubing hangers.

Related news