News - Press Release

Achieving project success through integration and trust

Integration, collaboration and trust between client and contractor were the key ingredients to achieving outstanding project success at the Trestakk field on the Norwegian Continental Shelf.

TechnipFMC won its first integrated Engineering, Procurement, Construction and Installation (iEPCI™) contract from Equinor (formerly Statoil) for its Trestakk field development in November 2016. The award originated directly from an integrated Front End Engineering Design (iFEED™) study awarded in February 2016.

Consisting of three production wells and two gas injection wells, the Trestakk development is a visionary example of how taking an integrated approach at project inception can simplify development solutions, significantly reduce cost and enhance overall client value.

“Integration and early collaboration have been essential to Trestakk,” Project Director Simen Andersen said. “We are using the advantages TechnipFMC offers to provide unique solutions that give our clients tremendous value beyond what a traditional approach would bring.”

“Trestakk is our first iEPCI™ project. This holistic approach is what makes development of this field doable. It also means that we assume greater responsibility due to the integrated delivery compared with development projects that are split into smaller packages. Trust is a prerequisite for working in this innovative way that ensures sustainable cost reduction,” Andersen said.

The Trestakk field is expected to start production in the second quarter 2019.

Building trust

Building and maintaining trust and collaboration between Equinor and TechnipFMC were key factors in achieving standout success at Trestakk. Creating a “one project atmosphere” helped support those efforts.

“Trestakk was originally seen as too expensive of a field to develop. But a strong collaborative effort between Equinor, TechnipFMC and other suppliers tackled that challenge by finding smarter, safer solutions that reduced costs by approximately 50 percent, making Trestakk financially viable,” said Rune Thoresen, Country Manager Norway and Senior Vice President Subsea Services.

“We’ve been talking a lot about working simpler and faster. The Trestakk success is a great example of how we are able to work that way and what a powerful difference it makes,” he said.

The Trestakk iEPCI™ contract was executed by one integrated project team. The iFEED™ study enabled TechnipFMC to integrate planning, mitigate risks, focus on critical interfaces early in the design process and influence fundamental technical decisions to optimize development and operation costs.

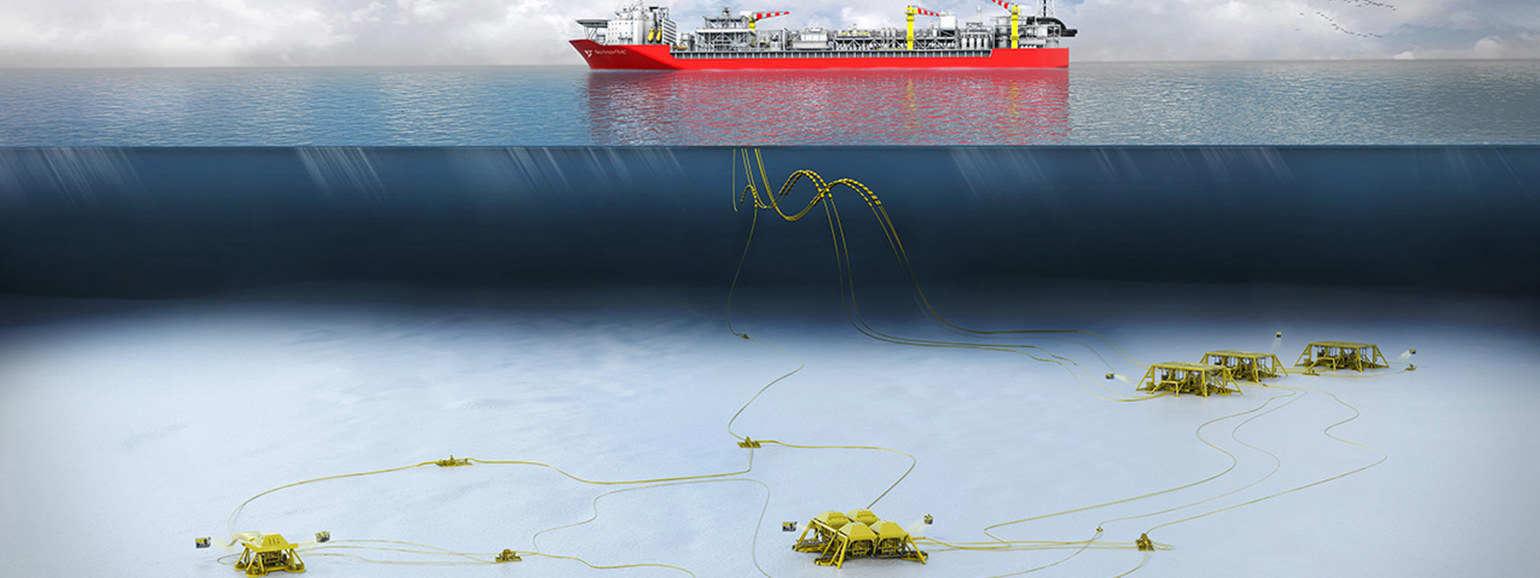

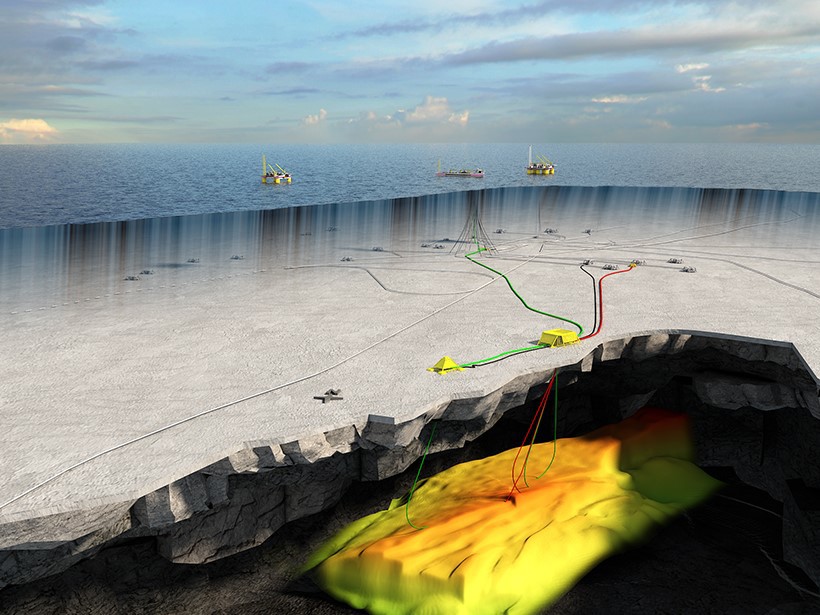

TechnipFMC supplied the flexible riser, production flowline, gas injection line, flexible jumpers, umbilicals and subsea production system. The production system includes the subsea trees and completion system, a manifold, wellheads, subsea and topside control systems and tie-in hardware and tools. All equipment was installed and delivered to the client at the seabed ready for operation.

TechnipFMC’s integrated approach to the project ensured added value for Equinor in a variety of achievements, including on schedule deliveries, significant savings through early commitment of line pipe, coating and raw material, marginal growth through system responsibility and zero interface concerns.

Other client successes were realized through TechnipFMC’s “one team, one goal” approach, including close client interaction through all project phases, optimized offshore campaign based on improved field layout, less documentation engineering on both sides, and significantly reduced estimates for rock installation.

Equinor Project Director Havard Stensrud said the iEPCI™ contract with TechnipFMC was a productive learning curve for both companies and the best solution for Trestakk.

“We have chosen an EPCI contract model, meaning that one supplier does everything: design, procurement, fabrication and installation of all subsea parts,” Stensrud said. “Normally we have several sub-deliveries and one final installation contract. The new contract model has been a learning curve on cooperation for us and the supplier, but I think we handled it well and I am sure this is the best solution for Trestakk.”

Positive changes

Senior Engineer Nikolai Gustavsen said TechnipFMC’s integrated approach to the Trestakk project “has led to many positive changes.”

“Because Trestakk prioritizes integration in every element, I feel part of its big picture and that’s motivating,” Gustavsen said. “Before, we would have delivered only part of the umbilical scope to the oil company, but now we are responsible for the whole scope.”

Contracts Specialist Gro Spets Firing said there were many lessons learned during the Trestakk project.

“I feel lucky to be on this project because it allows me to live the integration of our company and it’s not just something I’m hearing management talk about,” she said. “I’ve come from the subsea production systems side and the subsea umbilicals, risers and flowlines (SURF) area is new for me. Before the merger, our customer was in the middle if there was a problem to solve that impacted both areas. Now, we’re talking directly to each other and many of us even sit in the same office. It’s motivating to be part of delivering an even more effective result.”

Lowering costs

The integrated EPCI model offers better ways to capture opportunities and manage risk compared to split contract models. By taking full system responsibility, TechnipFMC could offer technical solutions and mitigate risks connected to its own equipment more efficiently than when interfacing with other contractors.

Operators generally preferred to award separate contracts for subsea equipment. By taking an integrated approach and involving suppliers earlier, superfluous components can be eliminated, design and installation streamlined and the combined schedule optimized, said Terje U. Eiken, Vice President Subsea Projects Norway.

“The Trestakk iEPCI™ contract executed by a single project team is a great example of how the industry can change through integration, and how suppliers and operators must adapt and cooperate to achieve sustainable cost improvements,” Eiken said.

One team, one goal

Arild Selvig, Vice President Subsea Commercial Norway and Russia, said that early collaboration flowing from the iFEED™ study was important and allowed the prioritization of “long lead items,” specialty equipment that has a long delivery period.

“That is when the supplier can influence the cost most. By working together as an integrated team, you build the trust and the joint understanding of the key value drivers of the operator,” he said. “Through early involvement, suppliers can devise and develop the best technical solution, schedule and execution model.”

Selvig said early engagement, the iFEED™ study and resulting iEPCI™ contract generated a high level of efficiency in the development of the Trestakk field. “This integrated process brings a sustainable framework for the lowest possible development cost and the most efficient execution model,” he said.

Knut Boe, Senior Vice President Subsea Projects, said the integrated approach is the wave of the future in subsea projects.

“The Trestakk project demonstrates that TechnipFMC can deliver real client benefits by integrating our products, systems and services,” Boe said. “Integration brings the lowest development costs and the most reliable, efficient and safe execution. We think it will gain an ever stronger foothold in the market.”

###

Equinor’s Trestakk field is located in the Norwegian Sea, with reservoir depths of nearly 4,000 m. TechnipFMC’s integrated approach added value for Equinor through a variety of achievements, including significant savings through early commitment of line pipe, coating and raw material.

More news

-

News | May 06, 2025

TechnipFMC Advances Hybrid Flexible Pipe Technology Innovation in Collaboration with Petrobras

-

News | March 18, 2024

Inside HISEP® – How TechnipFMC is taking dense gas separation and storage fully subsea

-

News | October 19, 2023

TechnipFMC wins NOIA ESG Excellence award