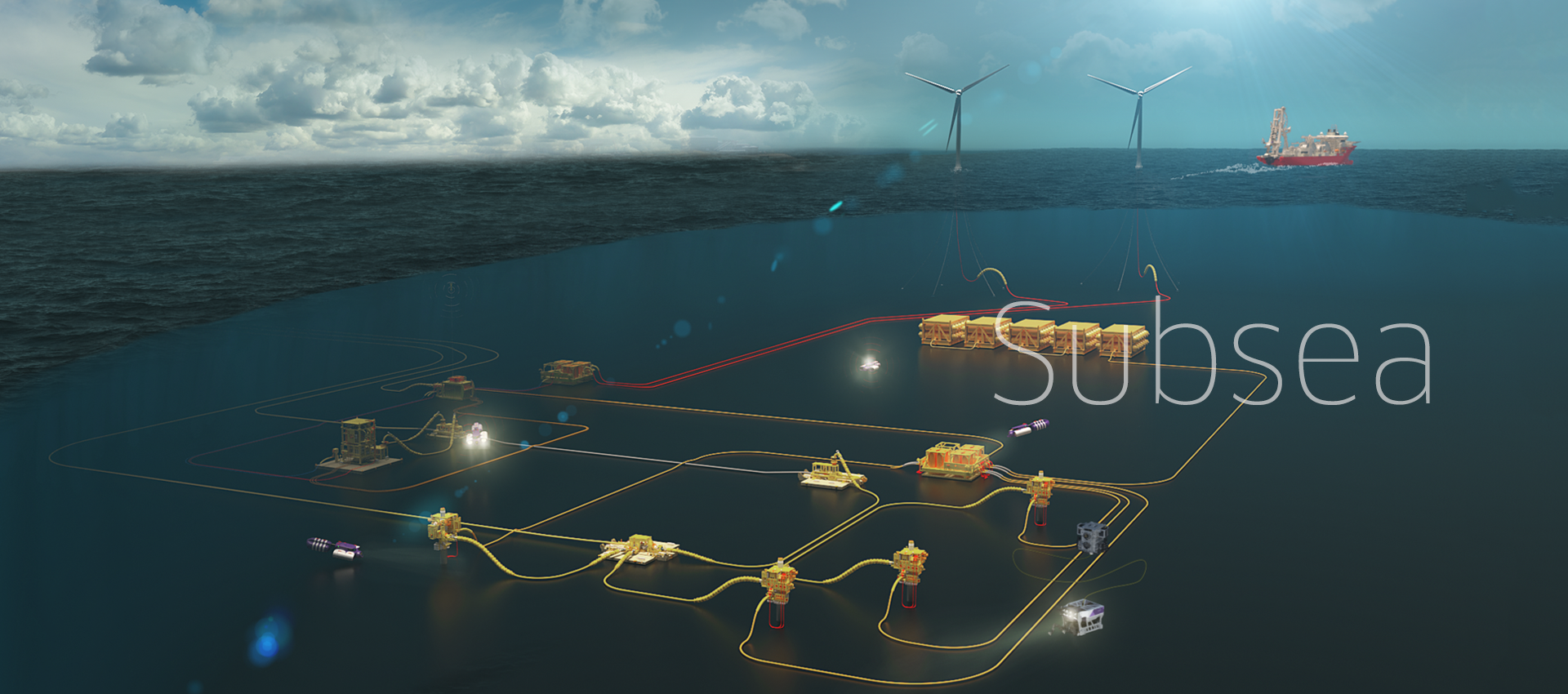

Optimizing subsea fields from concept to project delivery and beyond

Example intro text - this is optional

This component also has a wide block and image option, you can also edit the amount of padding. See below:

Example intro text - this is optional

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

c.21,000 Employees

38 Countries

1 Stock exchange listing - NYSE

$9.1bn Full year 2024 revenue

117 Nationalities

16 Vessels

Newcastle Upon Tyne

(Registered Office)

+44 (0)191 296 7000

Newcastle Upon Tyne, NE6 3PL

We are a global leader in energy projects, technologies, systems, and services and provide our clients deep expertise across subsea and surface projects.

We are leading the change and believe in innovation, smarter design and seamless ways of working. Our offerings range from individual products and services to fully integrated solutions with a single interface to ensure seamless execution.

We challenge convention by establishing new ways of working to enable improved and sustainable results for our clients. We reinvent our technologies, processes and approach to projects as we innovate end-to-end for greater efficiencies.

We collaborate in smart, meaningful ways that yield the greatest results and integrate our practices and technologies to simplify systems and streamline processes, accelerating the path to production and beyond.

We think ahead and seize opportunities for our clients, and act responsibly and openly, assuring them and our partner of our competence and inspiring their trust at every step.

All kinds of people with all kinds of skills drive TechnipFMC's success.

Our people work in manufacturing facilities, on vessels, in offices, and in the field, on and offshore.

Whatever role you take on, whatever team you are part of, we are proud to make sure you are in an environment where you will flourish.

Find the place where you belong today.

July 15, 2025

June 19, 2025

June 09, 2025

We challenge existing technologies and implement world-leading processes and practices at our exceptional manufacturing operations. Strategically located around the world, they ensure efficient delivery of our products, technologies, systems, and services to our clients.

Being part of our manufacturing teams gives you the opportunity to work across our business, potentially traveling the world as you expand your personal and professional horizons.

What is more, we are dedicated to making your time with us meaningful. You will benefit from on-the-job training, apprenticeships, support in further education and more. We will help you build all the knowledge and skills you need to enjoy the career you want.

TechnipFMC’s Subsea business deploys a worldwide fleet to support client projects with reliable assets, people, equipment, and expertise. We have 17 state-of-the-art vessels, specialised in a wide range of field activities. Rigid pipe-lay, diving support, and construction vessels offer a broad portfolio of options to meet project needs with tailored solutions.

More than 2,000 people work on our vessels worldwide, and each of them is key to our success. And so whatever role you take on, whatever team you are part of, we proudly ensure that you’re in an environment where you will flourish.

We have experience in marine operations dating back to the 1970s. Our mission is to provide a global integrated service, deploying our fleet to deliver international client projects. Our vessels are kitted out with technologies such as Remotely Operated Vehicles (ROVs) and flex-lay equipment – and, more importantly, they are crewed by experienced offshore people, who safely and efficiently operate our assets.

We manage a fleet of 30 best-in-class ROVs system,10 flex-lay towers, diving equipment and a plough for trenching activities in the North Sea. All this equipment is completely integrated onboard our vessels, and fully managed by the fleet.

You will find energetic, interactive, and supportive communities of colleagues in our offices, where everyone can find their own best ways to work.

There are individual desks for when you simply want to get your head down. Flexible seating lets you work away from your desk if you need to. Collaborative spaces foster creativity and learning through focused group work, while comfortable lounges help you clear your mind, catch up with colleagues, and find inspiration. We support flexible and hybrid working, so you do not have to be in the office all the time. But when you are there, you will find surroundings that offer everything you need to thrive.

Our global network of onshore service facilities offers fast-paced, dynamic environments at the cutting edge of operations. The exciting roles in our surface operations are where you’ll see our technologies in action, and our service teams working in perfect unison to drill, complete and extract hydrocarbons safely and sustainably.

No matter where you are in our onshore surface landscape, we will give you all the training and skills you need to work in the field. You will be part of an extraordinary team with the knowledge, confidence, and mindset to make sure they get the job done safely and efficiently – first time, every time.

A career in onshore subsea services puts you at the heart of our operations. Working from bases around the world, our onshore subsea teams are located near offshore operations in all major offshore basins.

They are the project management, supply chain, procurement, warehouse, logistics, and engineering teams. The workshop technicians and mechanics who mobilize equipment and tools and who keep them running, taking care of necessary recertifications, refurbishment and maintenance. They work with subsea production systems and tooling. Together, they play an integral role in keeping operations running smoothly.

Working on vessels and rigs, you will be part of an adventurous, challenging, dynamic and, above all, collaborative environment. You will be in a tightly knit, highly skilled international team focused on a common goal – keeping our offshore operations working smoothly and efficiently.

Our technical service personnel are there supporting our clients life of field operations, from equipment installation to plug and abandonment. They facilitate a wide range of operations, such as well interventions, Remotely Operated Vehicles (ROV) operations and maintenance.

Like everywhere at TechnipFMC, safety is paramount in this offshore environment, and training is rigorous – as well as your standard duties, you’ll be part of fire drills, search and rescue exercises, and more. It all goes towards building the exceptional camaraderie that is an integral part of this team.

What is your area of expertise? Choose from a career path below to see the opportunities currently available.

And do not forget to come back and check again – we are always looking for talented people to join our team.

SB Breakout BlockSB Breakout BlockSB Breakout BlockSB Breakout BlockSB Breakout BlockSB Breakout Block

HomePerson –Description

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

SB Five Five BlockSB Five Five Block

SB Five Five BlockSB Five Five Block

SB Five Five BlockSB Five Five Block

SB Image And Download List BlockSB Image And Download List Block

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

TechnipFMC’s Speedloc™-XT system is a fully digitized, hydraulic connector to remotely and safely connect and disconnect wireline pressure control equipment from the frac tree during wireline and coil tubing operations. Our system was developed from field-proven subsea technology to eliminate manual operations while improving focus on safety, operational efficiency and predictability.

WellFlex™ is the mid-to-large bore sizes of our iComplete™ SAFlex™ onshore flexibles portfolio. WellFlex™ flowlines deliver higher flow rates, improving slurry delivery and reducing operational costs and downtime. WellFlex™ enhances completion project economics with two simple connections, eliminating several iron connections between the manifolds and trees. With industry-standard clamp connections, WellFlex™ offers flexibility in rig ups and significantly reduces rig-up time.

TechnipFMC’s manifold systems are customizable for complete full-bore delivery through a rigid system or WellFlex™ solution. Our flexible modular systems are delivered and installed, either vertical or ground level, and connect to multiple frac trees before the pumping crew arrives.

Whether ground level or vertical, TechnipFMC’s Auto Greasing System eliminates costly manual greasing operations and red zone exposure, allows faster transition time between stages and takes greasing operations out of the critical path. This system is digital, scalable and can accommodate any shale pad configuration.

Focused on minimizing non-productive time and total cost of ownership on the frac pad, TechnipFMC's SuperFrac™ Large Bore Check Valve System has field-proven game-changing results. This modular, hydraulic fracturing check valve system has superior low-pressure sealing capabilities and is customizable to any frac pad.

We are continuing to transform the energy industry with the next generation of the iComplete™ SuperFrac™, purpose-built for pump swaps with flexibles. The SuperFrac™ QuickSwap™ is a pre-rig-in system that eliminates the need for all lifting devices and is configurable to any pad design.

PumpFlex™ is the small bore size of our iComplete™ SAFlex™ onshore flexibles portfolio. Providing OEM high-pressure flexibles to the oil and gas industry since 1979, the iComplete™ SAFlex™ onshore flexibles enhance completion project economics. Abrasion and corrosion resistant, PumpFlex™ offers flexibility in rig ups, absorbs vibration and reduces head loss and turbulence.

The CyberFrac™ system is a fully automated solution for controlling equipment operations during hydraulic fracturing. It enables well site managers and their teams to follow approved procedures and establish sitewide operational awareness through the Digital Handshake™ while reducing manual errors.

Accordion BlockAccordion Block

Accordion BlockAccordion Block

Accordion BlockAccordion Block

Accordion BlockAccordion Block