Remote Intervention Vehicle

The Future of Subsea Robotics

Riserless Light Well Intervention (RLWI)

A significant increase of production can be achieved in a very short timeframe intervening in existing wells.

Drilling a new well requires a rig, which needs to be contracted, and new production equipment, which needs to be built. This could take years.

With TechnipFMC’s RLWI, operators are able to increase production in a matter of months instead of years.

Increased Production. Now.

Increased Production

TechnipFMC’s agile approach to RLWI enables clients to drastically cut the average duration of intervention. Wells where production has decreased due to challenges (including well integrity, scaling, water production, reservoir depletion or equipment failure) can be addressed with RLWI.

Our RLWI technology reduces the cost of intervention compared to rig-based interventions by removing the need for a rig and a riser, resulting in:

Simpler operations

Significantly faster production

Drastically lower environmental footprint

Why Riserless Intervention?

On a 6-well gas-lift valve changeout campaign executed by TechnipFMC, an operator in the North Sea reported the following gains compared to a riser-based solution:

47 % time reduction

73 % OPEX savings ($36.7M)

80 % estimated CO2 emissions reduction

TechnipFMC’s RLWI key personnel have an average RLWI seniority of more than 14 years.

On a recent campaign in Angola, West Africa for one of the largest operators in the region, TechnipFMC proved our ability to quickly increase production from a subsea well through our RLWI technology compared to traditional riser-based operations:

The project was executed through a purpose-built RLWI vessel equipped for deepwater operations with coiled tubing downlines and with a new umbilical configuration. The acid stimulation scope was performed in combination with a stimulation vessel.

Water shut-off and acid stimulation operations for 3 wells in water depths between 1,000 and 1,900 m

Completed in just 27 days, including in-country mobilization, demobilization and transit to and from the field, with zero “Waiting on Weather” and minimal Non-Productive Time (NPT).

187t

50t

EMISSIONS

60t

16t

FUEL

120

65

POB

300-400t

70t

WEIGHT

Riser-Based Intervention

TechnipFMC’s RLWI

Lower Environmental Impact

RLWI results in significantly lower environment impact compared to rig/riser-based intervention:

Much shorter operations

Reduced Personnel on Board (POB), which results in less helicopter crew changes and supply vessels runs

Elimination of anchor handling vessels and time to moor the rig in shallow water

RLWI can safely work on dynamic positioning in less than 80 m. water

Less equipment and lighter equipment onboard requiring less power, which results in lower emissions

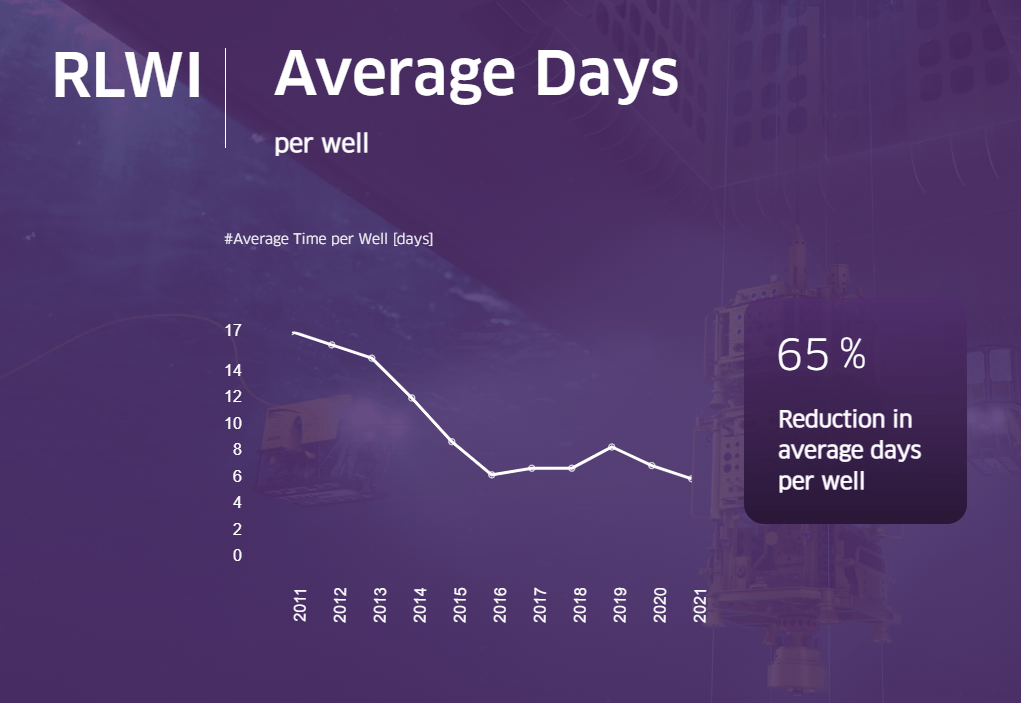

Experience Matters, and Efficiency Makes the Difference

Click on the legend to toggle between the systems

Number of wells per year

RLWI

Track Record

+

5200

+

Runs in hole

700

+

Well interventions

Per well

RLWI

Average Days

0

%

Reduction in average days per well

#Average days per well

Number of wells per year

RLWI

Track Record

7-year average

Typical RLWI Applications for Production Enhancement

Safety valve repair/replacement

Gas-lift valve replacement

Tree change-out

Acid stimulation/scale squeeze

Re-perforation

Water shut-off

Gas-lift retrofit

Well integrity repairs

Need intervention support?

Let us help you identify the best solution.