Subsea 2.0®

Our industrialized product platform that uses standardized components configured in a modular architecture

The current

dynamics

of the offshore

oil and gas

industry require:

Consistent and shorter delivery schedules

Field-proven technologies

Cost- control through dedicated & focused supply chain

Industrializing Subsea 2.0®

By industrializing our Subsea 2.0® platform, we can create value for our clients through a Configure-to-Order (CTO) engineering and manufacturing processes that meet client, field and industry specifications.

Our Subsea 2.0® configurable product platform consists of

pre-engineered products designed to provide the flexibility to accommodate customer needs and functional requirements.

By combining field-proven and new technologies, the product platform is configured using standardized components in a modular architecture.

This results in a Configured-to-Order (CTO) execution model providing simplification, standardization and industrialization. The outcome is zero product engineering, optimized supply chain, repeatable manufacturing and predictable deliveries.

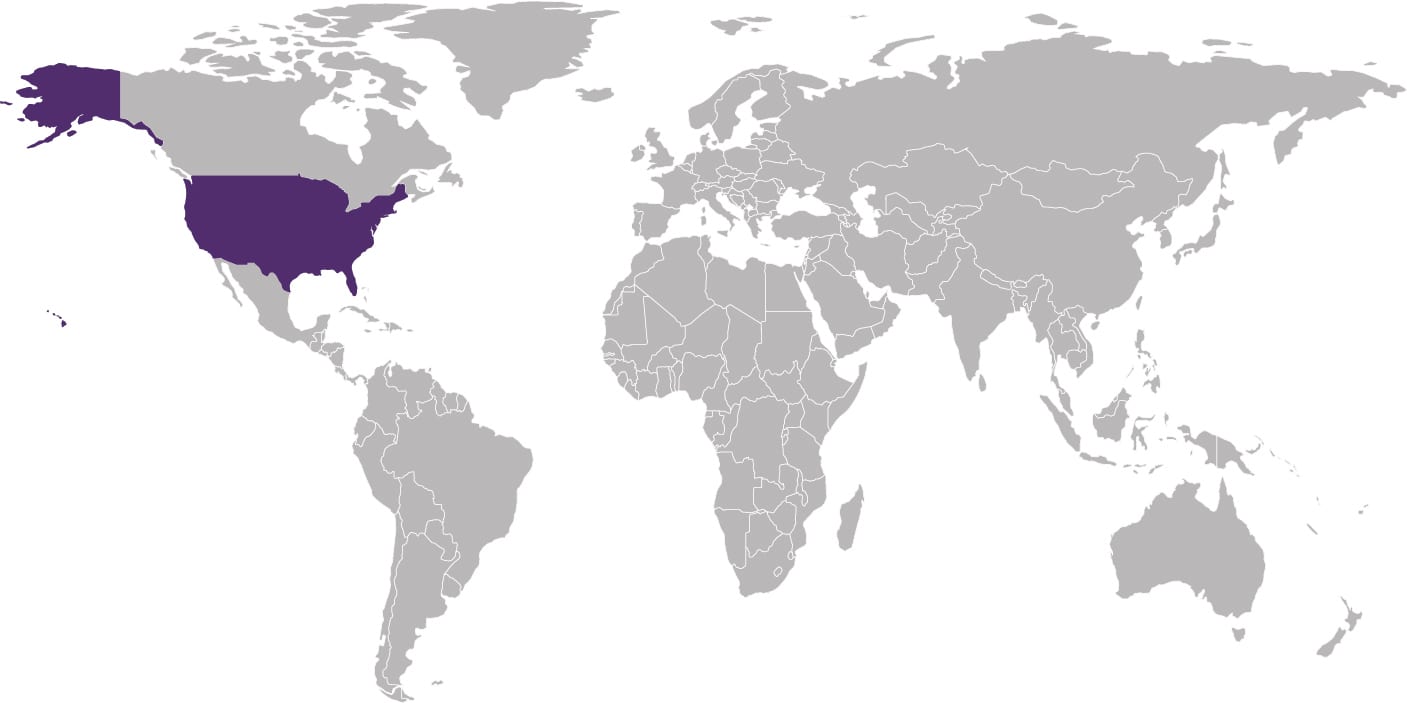

Current as of Q3 2024

Gulf of Mexico

Clients

0

Projects

0

EQUIPMENT AWARDED

0

Installations

0

South America

Clients

0

Projects

0

EQUIPMENT AWARDED

0

Installations

0

UK & Mediterranean

Clients

0

Projects

0

EQUIPMENT AWARDED

0

Installations

0

West Africa

Clients

0

Projects

0

EQUIPMENT AWARDED

0

Installations

0

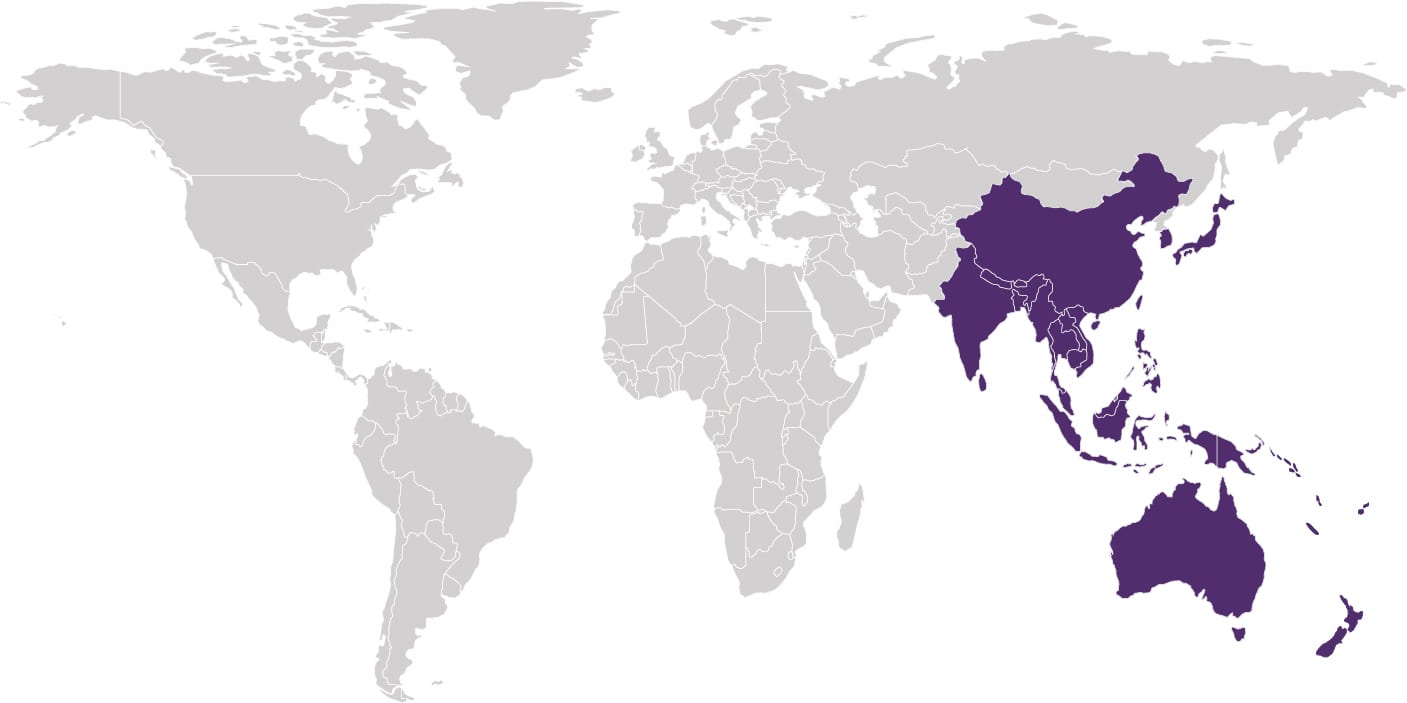

Asia-Pacific

Clients

0

Projects

0

EQUIPMENT AWARDED

0

Installations

Installations

0

Global

Installations

41

EQUIPMENT AWARDED

261

Projects

41

Clients

18

It’s your subsea equipment. Configured to order.

Subsea 2.0® CTO offers the best of both worlds, combining a custom configured tree with the safety and reliability of standardized parts and processes.

We drive value through partnerships in every aspect of our business, leveraging shared knowledge for maximum impact.

Reach out to us for more information on our product catalog.

Production or Injection Module

Common module shared across horizontal and vertical tree systems

Can be configured for gas or oil production, or water or gas injection

Can be fitted with optional resident meter or subsea retrievable meter

Core Module

Options of vertical tree with tubing head, vertical in-the-wellhead tree, or horizontal tree to meet client-specific requirements and preferences

10,000 or 15,000 psi operating pressure

Pre-engineered and configurable architecture provides over 500 major tree configurations

Tree system comes with different insulation options to meet project cooldown requirements

Annulus Module

Common module shared across horizontal and vertical tree systems

Optional gas lift injection point, with or without single phase flow meter

Electric and Hydraulic Control Module (EHCM)

Common module used across all tree systems

Features TechnipFMC’s latest controls offering, our 800 series

Can be configured with chemical injection monitoring valves (CIMV)

Optional high-flow methanol injection point

Subsea 2.0®

Tree – Modular design

The Subsea 2.0® tree architecture has been developed on a modular arrangement with a high focus on commonality between horizontal and vertical tree systems.

Consistent and shorter delivery schedules

Field-proven technologies

Cost- control through dedicated & focused supply chain

1

2

3

4

5

Consistent and shorter delivery schedules

Field-proven technologies

Cost- control through dedicated & focused supply chain

Manifold

Modular design

The Subsea 2.0® manifold architecture was engineered utilizing the same philosophy as the tree systems. Utilizing pre-designed components and compact blocks, our manifold offering delivers flexibility in functionality.

Industrialization of

Subsea 2.0® Manufacturing

With our dedicated Subsea 2.0® manufacturing facility in Nusajaya, Malaysia, we increase efficiency and enable predictable execution through our lean manufacturing practices and standardization of products.

3

Consistent and shorter delivery schedules

Field-proven technologies

Cost- control through dedicated & focused supply chain